This guide covers pellet plant project types, key planning steps, investment analysis and success factors, helping you build an efficient and profitable pellet production facility.

Against the backdrop of global energy transition and sustainable agriculture promotion, the pellet plant project has emerged as a high-potential investment option. Converting abundant agricultural and forestry wastes into high-value pellet products (such as biomass fuel pellets, feed pellets, and fertilizer pellets) not only achieves resource recycling but also brings stable economic benefits. However, a successful pellet plant project requires systematic planning covering raw material sourcing, equipment selection, process design, and market positioning. This article provides a comprehensive guide to pellet plant projects, helping investors, entrepreneurs, and industry practitioners grasp the core essentials and avoid common pitfalls.

Please see the details below:https://pelletmakingmachine.com/pellet-making-machine-for-sale-australia/

Main Types of Pellet Plant Projects: Align with Market Demand

Pellet plant projects can be classified into different types based on product orientation, and choosing the right type is the first step to ensure project success. The main types and their market prospects are as follows:

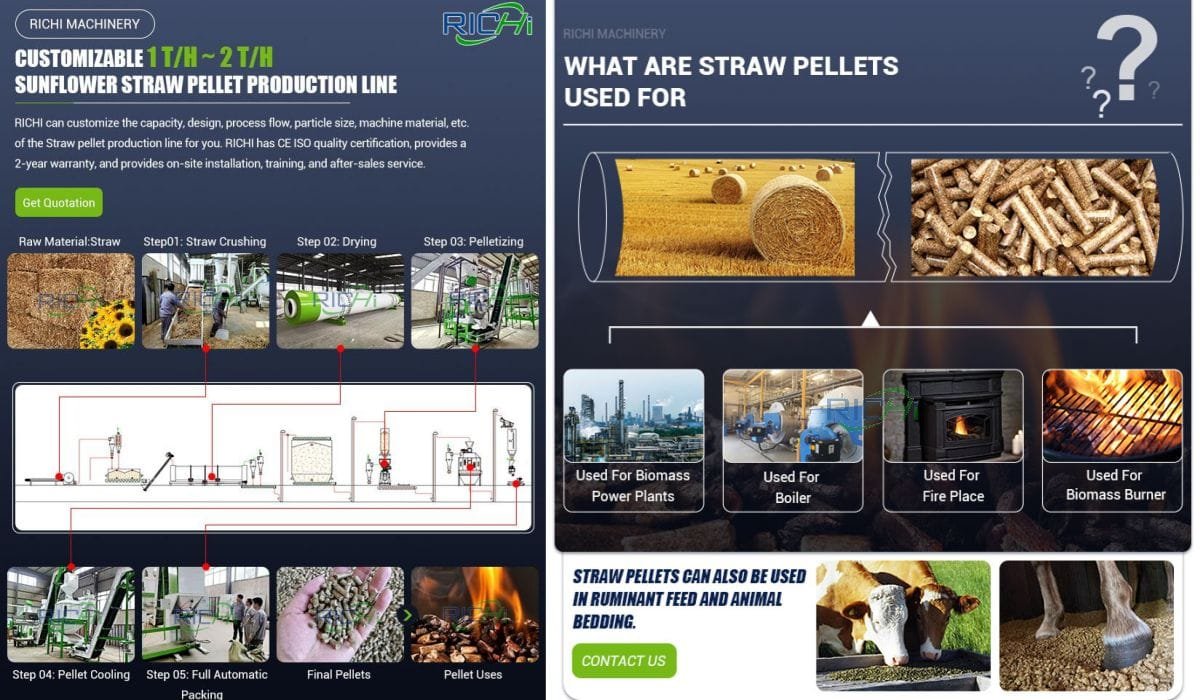

- Biomass Fuel Pellet Plant Project: As a core part of the renewable energy industry, this type of project processes wood chips, sawdust, straw, rice husks and other agricultural and forestry wastes into high-density fuel pellets. The finished products are widely used in residential heating, industrial boiler combustion, and biomass power generation. Driven by global carbon neutrality goals, the global wood pellet market is expected to reach $16.75 billion by 2027 with a CAGR of 7.28%, making this project type have broad market space.

- Feed Pellet Plant Project: Focused on the animal husbandry industry, this project processes corn, soybean meal, forage grass and other raw materials into nutritionally balanced feed pellets. The pellet feed has the advantages of high digestibility, low waste rate, and convenient storage, which is in line with the development trend of intensive livestock breeding. It is suitable for investment in regions with developed animal husbandry.

- Fertilizer Pellet Plant Project: This project converts livestock and poultry manure, compost, and other organic wastes into granular organic fertilizers or compound fertilizers. It not only solves the environmental pollution problem of waste accumulation but also meets the growing demand for green fertilizers in agricultural production. With the promotion of ecological agriculture policies, this project type has significant policy support advantages.

Core Planning Steps for Pellet Plant Project: Lay a Solid Foundation for Success

A scientific and systematic planning process is the key to reducing project risks and improving operational efficiency. The core planning steps of a pellet plant project include the following aspects:

- Feasibility Study & Raw Material Sourcing: The feasibility study should focus on raw material availability, market demand, and policy environment. Raw material is the cornerstone of the project—its quantity, quality, and transportation cost directly determine the project’s profitability. It is necessary to confirm the long-term supply stability of raw materials (such as signing long-term supply contracts with local farms or forestry enterprises) and control the transportation distance to reduce costs. For example, wood pellet projects should be built near forestry areas or sawmills to minimize the transportation cost of wood chips and sawdust.

- Plant Site Selection & Layout Design: The site should be selected in areas with convenient transportation (close to highways, railways, or ports) and complete supporting facilities (stable power supply, water supply). The layout design should follow the principles of process rationality, convenient maintenance, and safety and environmental protection. It is necessary to set up independent areas for raw material storage, production processing, finished product storage, and office areas, and reserve space for future expansion. At the same time, sufficient safety distance should be maintained to prevent dust explosion risks.

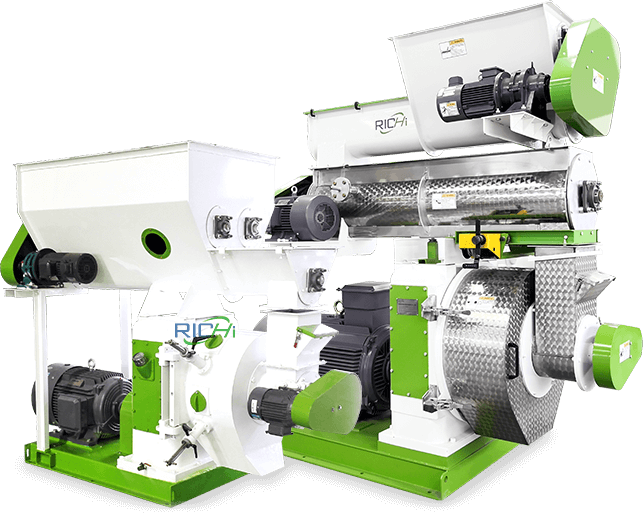

- Equipment Selection & Process Configuration: Equipment selection should match the project scale and product type. A standard pellet production line usually includes crushing equipment, drying equipment, pelletizing equipment, cooling equipment, screening equipment, and packaging equipment. For small-scale projects (daily output <5 tons), cost-effective flat die pellet machines can be selected; for medium and large-scale projects (daily output >20 tons), high-efficiency ring die pellet machines or double roller extrusion granulators are more suitable. It is recommended to choose equipment with reliable quality and perfect after-sales service to reduce later maintenance costs. In addition, configuring intelligent control systems and dust removal equipment can improve production efficiency and meet environmental protection standards.

- Policy Compliance & Environmental Protection Design: It is necessary to understand the local industrial policies, environmental protection standards, and tax preferential policies. The project must pass environmental impact assessment, and the production process should meet the requirements of waste gas, waste water, and noise emission standards. For example, installing pulse dust collectors can effectively control dust pollution, and using low-noise motors can reduce noise interference to the surrounding environment. At the same time, actively applying for agricultural and forestry waste utilization subsidies can reduce the initial investment pressure.

Investment Analysis & Profit Outlook of Pellet Plant Project

The investment cost and profit of pellet plant projects vary with scale, product type, and regional differences. Taking the common biomass pellet project as an example, the investment and profit analysis is as follows:

- Investment Cost Composition: The investment cost mainly includes fixed assets investment and working capital. Fixed assets investment covers equipment purchase (accounting for 40%-60% of the total investment), plant construction, and infrastructure supporting (such as power distribution and water supply). According to market data, the investment cost of a small biomass pellet plant (daily output 2-5 tons) is about $10,000-$30,000, while that of a large-scale plant (daily output 50 tons above) can reach $100,000-$200,000. Working capital is used for raw material purchase, personnel salaries, and daily operation.

- Profitability Analysis: The profit margin of pellet products is relatively stable. Taking wood pellet products as an example, the processing cost per ton is about $40-$60, and the market selling price is $80-$120, with a gross profit margin of 30%-50%. A medium-sized biomass pellet plant with a daily output of 15 tons can achieve an annual output of about 4,500 tons, and the annual gross profit can reach $180,000-$270,000. The payback period of most pellet plant projects is 1-3 years, and the internal rate of return (IRR) can reach more than 20% under stable operation conditions.

- Key Factors Affecting Profitability: Raw material cost is the most important factor affecting profits—controlling raw material procurement cost can directly improve profit margins. In addition, product quality, market channels, and operational efficiency also have a significant impact. High-quality pellets (such as low-ash, low-moisture wood pellets) can obtain higher selling prices, while establishing stable sales channels (such as long-term cooperation with power plants or heating companies) can ensure continuous product sales.

Key Success Factors for Pellet Plant Project: Avoid Risks & Improve Efficiency

Based on the experience of numerous successful pellet plant projects, the following key factors can help improve the project’s success rate:

- Ensure Raw Material Stability: Establish a diversified raw material supply channel to avoid production interruption caused by insufficient raw material supply. At the same time, strengthen the pretreatment of raw materials (controlling moisture content at 10%-15% and particle size below 5mm) to improve pelletizing efficiency and product quality.

- Focus on Equipment Maintenance & Standardization: Adopt standardized equipment components to reduce the types of spare parts and simplify maintenance. Regularly maintain key equipment components (such as pellet machine molds and pressure rollers) to extend their service life and reduce downtime. It is recommended to cooperate with equipment manufacturers that provide timely after-sales service to solve equipment failures quickly.For details regarding pellet mill sales, please see Pellet Mill For Sale Canada.

- Strengthen Quality Control: Establish a complete quality control system to monitor product quality throughout the production process. For example, regularly test the moisture content, density, and calorific value of finished pellets to ensure that products meet market standards. High-quality products can help establish a good brand image and gain long-term market trust.

- Optimize Logistics & Market Layout: Choose a reasonable product sales model according to the project scale. Small-scale projects can focus on local and surrounding markets, while large-scale projects can explore export markets (such as European and North American biomass energy markets) by virtue of port location advantages. Optimizing transportation methods (such as using bulk transportation for large orders) can reduce logistics costs.(visit site)

Conclusion: Seize the Opportunity to Build a High-Quality Pellet Plant Project

Under the tide of global low-carbon development and sustainable agriculture, the pellet plant project has broad development prospects. It not only realizes the resource utilization of agricultural and forestry wastes but also brings considerable economic benefits to investors. However, the project requires systematic planning from feasibility study, site selection, equipment selection to operation management.

Richi manufacture is dedicated to developing various pellet plant projects.By grasping the core planning points, controlling investment risks, and focusing on product quality and operational efficiency, you can successfully build an efficient and profitable pellet plant project. If you need more professional support such as project feasibility analysis, equipment selection, and process design, welcome to consult our professional team to help you seize industry opportunities and achieve project success.