Agricultural straw is one of the most abundant yet underutilized resources in many farming regions. Every year, large quantities of wheat straw, rice straw, corn stalks, and similar residues are produced after harvesting. With increasing pressure to reduce waste and improve resource efficiency, pelletizing straw has become a practical solution. A modern straw pellet machine enables producers to transform loose, bulky straw into compact pellets suitable for fuel, bedding, and agricultural reuse.

Why Straw Pelletizing Is Gaining Attention

Loose straw is difficult to transport, store, and use efficiently. It occupies large storage space, generates dust, and is often disposed of through open burning, which creates environmental concerns. Pelletizing addresses these issues by compressing straw into uniform shapes with controlled moisture and density.

Straw pellets are widely valued because they:

- Improve logistics efficiency

- Reduce handling and storage costs

- Offer consistent performance in end-use applications

As sustainability policies expand worldwide, straw pellet production is becoming a long-term industry rather than a short-term trend.

Core Functions of a Straw Pellet Machine

A straw pellet machine is specifically designed to process fibrous plant materials that do not naturally bind easily. During operation, chopped straw is compressed by rollers and forced through a die, where heat and pressure activate natural lignin to form solid pellets.

Compared with simple briquetting or baling, pelletizing offers:

- More uniform size and shape

- Better compatibility with automated systems

- Higher market acceptance

Well-designed pellet machines focus on stability, wear resistance, and continuous operation, especially when dealing with abrasive straw fibers.

(Related Post: https://biomasspelletizer.com/straw-pellet-machine/)

Complete Straw Pellet Production Line System Structure

For commercial-scale projects, pelletizing is usually part of a broader system rather than a standalone step. A complete straw pellet production line system integrates multiple processing stages to ensure consistent quality and high efficiency.

Typical System Workflow

A full production line may include:

- Straw receiving and pre-treatment

- Size reduction and controlled feeding

- Drying or moisture adjustment

- Pelletizing and shaping

- Cooling, screening, and packaging

This integrated approach reduces downtime, improves product uniformity, and allows easier process control for operators.

Adapting to Different Straw Sources

Straw materials vary significantly depending on crop type, harvest method, and regional climate. Modern pellet systems are designed to handle this variability with flexible configurations.

For instance:

- Rice straw with higher moisture may require drying

- Wheat straw often needs finer crushing

- Mixed straw materials can be processed after blending

This adaptability allows producers to utilize locally available residues instead of relying on a single raw material source.

Evaluating Performance and Investment Factors

When planning a straw pellet project, investors typically consider output stability, energy usage, and maintenance requirements. Equipment durability is particularly important, as straw fibers can accelerate wear if machines are not properly designed.

Before finalizing a project, reviewing existing installations can be highly beneficial. You can try this web-site to explore different straw pellet system layouts and understand how real-world projects manage raw materials, capacity, and operational challenges.

Applications of Straw Pellets in Energy and Agriculture

Straw pellets are widely used as biomass fuel in heating systems, industrial boilers, and decentralized energy facilities. Their uniform size allows smooth feeding and stable combustion, making them suitable for automated fuel systems.

In agriculture, straw pellets are commonly used as:

- Animal bedding with good absorbency

- Raw material for composting

- Supplementary roughage in specific feeding programs

These diverse applications help producers reduce market risk by serving multiple industries.

Choosing the Right Equipment Partner

Equipment selection plays a critical role in long-term production success. Beyond machine specifications, factors such as engineering experience, system integration, and technical support should be carefully evaluated.

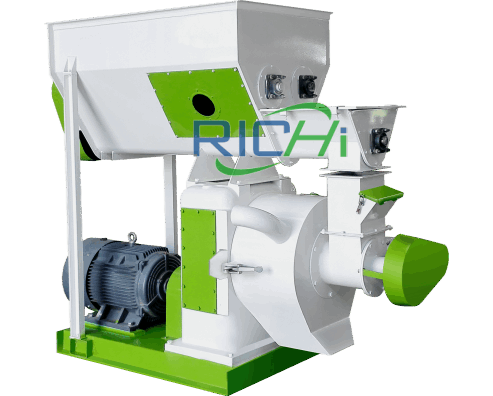

Richi Machinery Manufacture has been involved in biomass pellet equipment development for many years, offering solutions for straw-based pellet production across different capacity ranges. Working with experienced manufacturers helps ensure smoother installation, better system matching, and more reliable operation over time.

Long-Term Outlook for Straw Pellet Production

As agricultural sustainability and renewable energy remain global priorities, straw pellet production is expected to maintain steady growth. By converting low-value residues into standardized pellets, producers can improve resource utilization while creating new revenue streams.

With a suitable straw pellet machine and a properly designed complete straw pellet production line system, agricultural waste can be transformed into practical products that meet modern environmental and industrial needs.